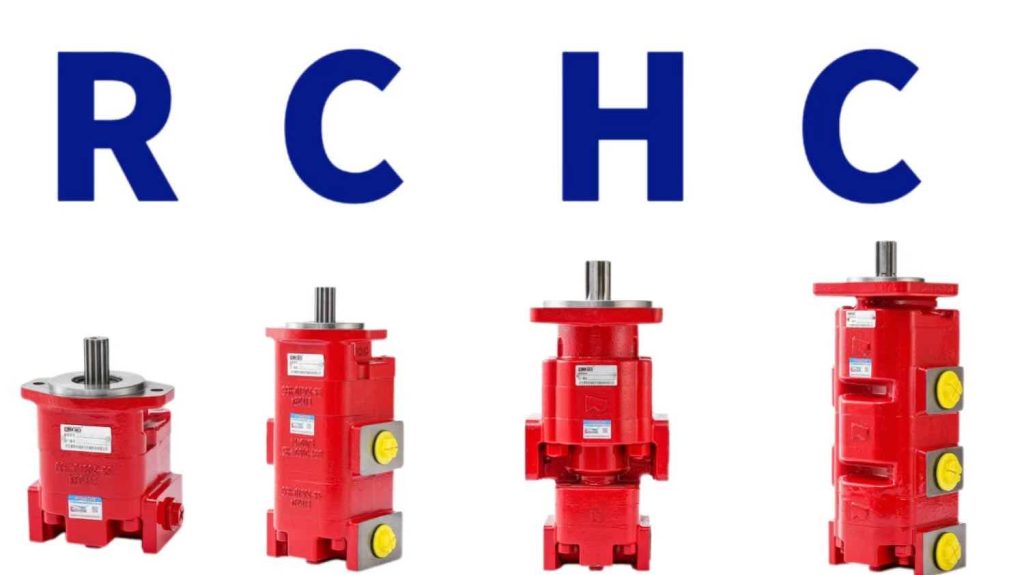

Shandong Ruichen hydraulic PGP640

Shandong Ruichen Hydraulic PGP640 series hydraulic gear pump is a high-performance industrial equipment, widely used in heavy machinery, agricultural machinery, construction equipment and other industries. As one of the flagship products of Ruich...

عرض التفاصيل الشركة المصنِّعة لمنتجات المضخات الهيدروليكية |شركة روي تشن للماكينات الهيدروليكية. المحدودة

الشركة المصنِّعة لمنتجات المضخات الهيدروليكية |شركة روي تشن للماكينات الهيدروليكية. المحدودة

مرحباً بكميرجى تسجيل الدخول