Analyse des causes d'un mauvais réglage de la pression du système hydraulique

① The set pressure of the relief valve is improper

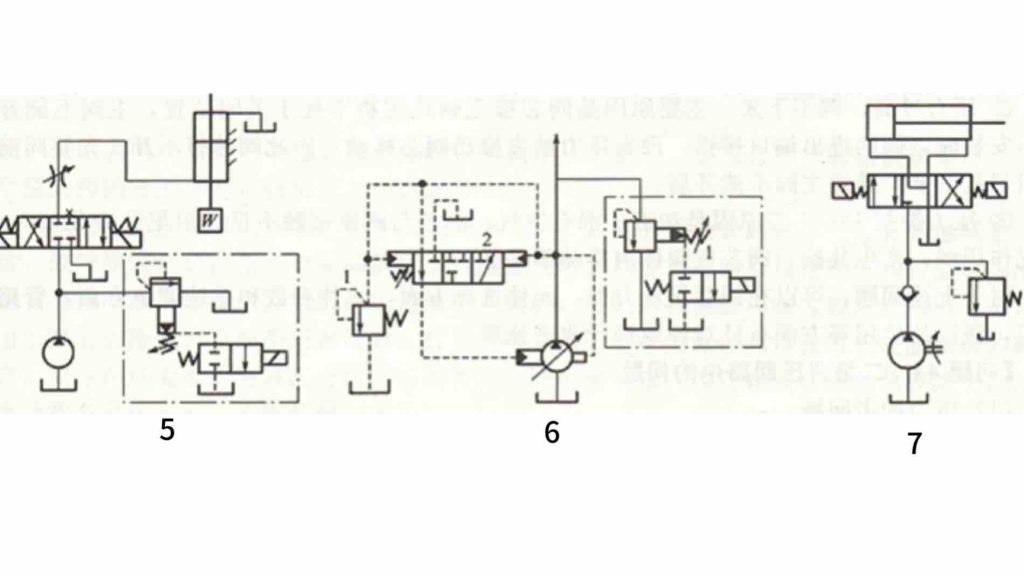

The improper setting pressure of the relief valve causes the movement speed of the hydraulic cylinder to fail to meet the requirements. Figure 5 The loop requires smooth movement when lifting, large speed adjustment range, and the piston can be stopped at any position. However, during operation, when adjusting the rising speed of the lift, the speed does not change in a large range, and only when the throttle opening is adjusted to a very small, the rising speed changes, and the performance requirements cannot be met. This is because the pressure of the relief valve has been raised. The set pressure of the relief valve should be the sum of the pressure drop required when the working pressure of the hydraulic pump is exactly equal to the load pressure of the hydraulic cylinder and the total flow of the pump through the throttle valve.

② Improper pressure setting parameters

Improper setting of hydraulic cylinder pressure leads to excessive oil temperature of constant pressure pump oil supply system. As shown in Figure 6, due to improper pressure setting parameters, the oil temperature during the operation of the hydraulic system is too high. The above reason is that the system pressure Pr adjusted by the pressure valve 1 is lower than the pressure Pt adjusted by the pressure regulating spring of the valve 2, so that the constant pressure pump always works at the maximum displacement, and the excess flow is overflow back to the tank with the pressure Pr, and all of it is converted into heat, so that the temperature of the hydraulic system is increased. Therefore, the valve 1 is used as a safety valve. Adjust its pressure to 0.5 ~ 1MPa greater than the maximum pressure required by the system, and the above problem can be solved.

Fabricant de produits de pompe hydraulique | Rui Chen Hydraulic Machinery Co. Ltd

Fabricant de produits de pompe hydraulique | Rui Chen Hydraulic Machinery Co. Ltd

BonjourVeuillez vous connecter