Points d'installation des équipements de moteurs hydrauliques

Hydraulic motor is an important power source widely used in modern industrial equipment. When installing hydraulic motor, it is necessary to pay attention to the following key points to ensure the efficient operation and long-term stability of the equipment.

- Prepare for installation

Before installing the hydraulic motor, it is first necessary to ensure that all components of the hydraulic system are in good condition, especially whether the combination of the motor and the hydraulic oil circuit system meets the requirements. Carefully check the specifications of the gear motor and the plunger motor to ensure that they meet the design requirements. For occasions where high performance is required, high-speed motors can be selected to ensure that their speed and load can meet the working requirements.

- Positioning and fixing

During the installation process, the hydraulic motor must be accurately positioned in strict accordance with the requirements of the design drawings. Whether it is a quantitative motor or a two-way hydraulic motor, it is necessary to ensure that the mounting base of the motor is smooth, bolted and reaches the specified torque to prevent loosening caused by vibration or long-term operation. At the same time, ensure that the motor and the drive device are firmly connected, such as the hydraulic direct drive motor needs to work closely with other mechanical devices to ensure smooth operation.

- Connection of hydraulic system

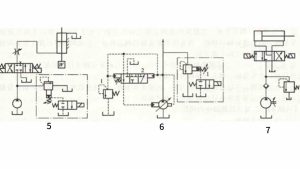

Special attention should be paid to the connection of the oil inlet and outlet pipes of the hydraulic motor, which must be correctly connected according to the hydraulic schematic diagram to prevent wrong connection or oil leakage. When using the hydraulic drive device, special attention should be paid to the tightness of the oil circuit to ensure no leakage. After the pipe connection is complete, a thorough inspection must be carried out to ensure that all joints are tight and correct.

- Configure the control system

The control system configuration of hydraulic motor is the key to its efficient operation. In modern industry, more and more equipment uses automatic control systems to achieve more precise operation. During the installation, ensure that the pressure compensation and flow regulation functions are correctly configured to prevent system faults caused by improper flow or pressure. For remote operation requirements, remote control devices can also be configured to facilitate the operator to monitor and adjust the equipment status in the control room.

- Safety braking system

In some operating environments, the brake motor function of the hydraulic motor is essential. Especially when the equipment needs to be started and stopped frequently or stopped under load, the brake motor can ensure that the equipment is stopped safely in an emergency to prevent mechanical damage or personnel injury.

- Trial operation and debugging

After installation, a trial run must be carried out. In the trial operation, it is necessary to check whether the functions are normal, especially whether the link load regulation is sensitive, and whether the control system can respond to changes in the workload in time. At the same time, it is necessary to detect whether the pressure and flow of the hydraulic system are within the design range to ensure that the hydraulic control and electric liquid control system are working normally.

Fabricant de produits de pompe hydraulique | Rui Chen Hydraulic Machinery Co. Ltd

Fabricant de produits de pompe hydraulique | Rui Chen Hydraulic Machinery Co. Ltd

BonjourVeuillez vous connecter