Customer feedback

RCHC Hydraulic Machinery Manufacturing Co., Ltd. is a gear pump and steering valve manufacturer. RCHC hydraulic products are exported to many countries around the world Turkish customers who have already purchased from us say that this ...

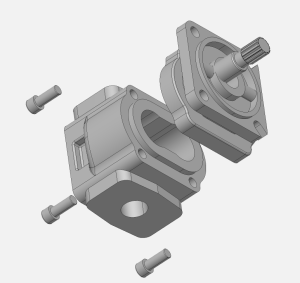

View details Hydraulic Pump products manufacturer | Rui Chen Hydraulic Machinery Co. Ltd

Hydraulic Pump products manufacturer | Rui Chen Hydraulic Machinery Co. Ltd

HelloPlease log in